Manufactures

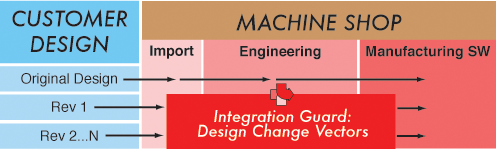

The Problem: Customers send designs and revisions in many different CAD formats. Manual re-engineering for each change imported from a customer imposes significant delay, cost and risk of errors. Alternately, supporting multiple CAD platforms to match each customer’s system simplifies updates but imposes high licensing and staffing costs.

The Solution: Regardless of what CAD format your customers use now, or in the future, all future revisions will act in your system as if they were native edited changes. This ensures a sustained integration to your manufacturing software and other engineering applications.

The Solution: Regardless of what CAD format your customers use now, or in the future, all future revisions will act in your system as if they were native edited changes. This ensures a sustained integration to your manufacturing software and other engineering applications.

The best part is that DCV works purely within your system. There are no preconditions or dependencies on how your customers send you the CAD file. Once you convert it to a solid body, you can integrate updates to your engineering applications.

Product Design Teams

The Problem: Smooth communication across large teams is critical to delivery time, cost and quality. CAD is the heart of communication for complex product design information. Unfortunately communication across disparate CAD systems is problematic at best. Manual re-engineering to update manufacturing, analysis or planning software using a different CAD format is not the solution you want. Each manual step adds to the risk of delays or errors.

Policies aimed at ensuring that all stakeholders use a uniform CAD environment are a possible solution but often fall short in practice (as with the Airbus A380 case). Any exception to that uniform environment becomes a risk but periodic software updates, acquisitions or new partnerships will always introduce change. Even when such policies are effective they impose a significant policy burden and limit flexibility.

The Solution: With DCV® design changes can be automatically implemented in each stakeholder’s native CAD environment. By applying a change vector based on geometric comparison (instead of just translating over the new version) your preserve the context data and entity identifiers used to integrate to the design. This enables reliable sustained integration across CAD platforms.

System Integration

The Problem: Upgrading or migrating an enterprise from one CAD format to another is a significant challenge. There are many stakeholders and applications depending on data from those designs for ongoing design projects.

The Solution: DCV can make CAD migration or integration projects far more flexible and forgiving. DCV can bridge the gap during migration between the old and new systems so that both sides receive updates that act like their native format. DCV can even clean up problems in a data migration project after changes have been simultaneously made in multiple different systems to the same design. Simply “add the vectors” to sync both versions while protecting integrations to other applications.

Software Providers

The Problem: CAD and engineering applications want to help their users work smoothly with data from any source but translators fall short on protecting associativity and supporting multiple CAD platforms is a huge effort.

The Solution: Integrating DCV into your application provides your users with associativity to data from any source format. In addition to helping everyday operations that makes it easier for them to migrate data into your software when they first buy it.